APHONIC BOX MINI CASTLE DOUBLE SUCTION TRANSMISSION

MCT 9/9

MCT series fan boxes are equipped with centrifugal double inlet transmission fan. Mounted motors are asynchronous three-phase IEC V. 230/400 Hz 50 or V. 400/690 Hz 50 IP 55 CLASS F. Dual polarity 4/6 Poles motors (1,400 - 900 RPM) are available on request. The temperature of the conveyed fluid must not exceed 40°C.

Key Features

The MCT series consists of the MCD elements with the addition of:

- Extruded aluminum frame with fiberglass or cast aluminum corners

- Panels made of polyurethane foam sheets with external - internal coating consisting of embossed aluminum films

- Fully recyclable internal aphonization made of thermobonded polyester fibers with reaction to fire "Class 1 (UNI 9177:1987) Euroclass B s1 d0" and smoke "F1 (AFNOR NF F16-101:1988)" certified with 20 mm thick aluminum protective foil

- Engine side inspection hatch

- Fan attached to the pressure port with gaskets

- vibration dampers and by means of vibrostops on the feet

- Base and counter-base with interposed

- vibrostop

- Belt tensioner slides

- Transmission with V-belts and pulleys

- Steel panels

Accessories

- Cerebro and/or Easy series switchboard

- Speed controller (single phase)

- Galvanized sheet metal rain canopy

- Wolf's mouth with anti-volatile net on presser

- Engine side inspection hatch

- Supporting feet

- Polished Stainless Steel Panels

- Standard dimensions can be varied by customer order and design

Technical characteristics

1,1

3PH

2,6

1590

QE Cerebro / Easy

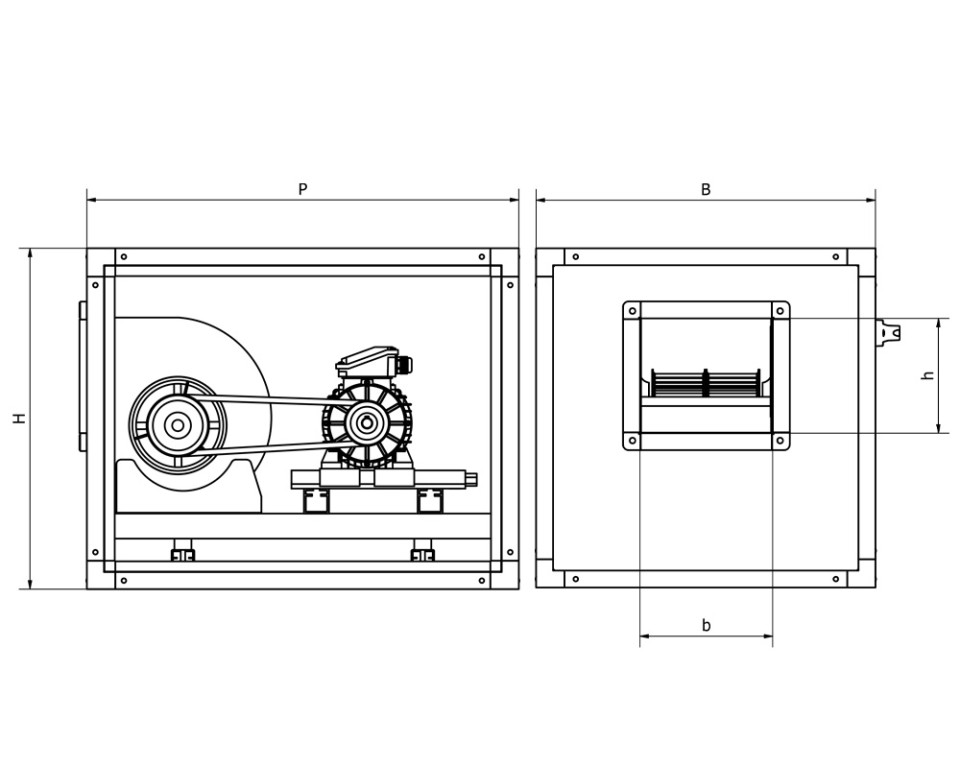

Dimensions

660x860x660

298

261

62

CIMI Srl reserves the right to change dimensional dimensions and/or performance for improvements or range changes without what is on the site being binding.

The reported data meet the following parameters:

- - Tolerance on flow rate ±5%

- - Noise tolerance +3dB(A)

- - Air temperature 15°C

- - Barometric pressure 760 mm Hg

- - Air specific gravity 1.226 kg/m³

- - Frequency 50 Hz

Sound pressure level was measured by omnidirectional free-field measurement at 1.5 or 3 m (depending on the product) from the fan with ducted inlet, tolerances, performance points and environments according to European standards.

Flow rate tolerance ±5% | Noise tolerance +3dB(A) | Air temperature 15°C | Barometric pressure 760 mm Hg | Air specific gravity 1.226 Kg/m³ | Frequency 50 Hz

The sound pressure level was measured with omnidirectional free-field measurement at 1.5 or 3 m (depending on the product) from the fan with ducted inlet, tolerances, performance points and environments according to European standards."

The MCT series consists of the MCD elements with the addition of:

- Extruded aluminum frame with fiberglass or cast aluminum corners

- Panels made of polyurethane foam sheets with external - internal coating consisting of embossed aluminum films

- Fully recyclable internal aphonization made of thermobonded polyester fibers with reaction to fire "Class 1 (UNI 9177:1987) Euroclass B s1 d0" and smoke "F1 (AFNOR NF F16-101:1988)" certified with 20 mm thick aluminum protective foil

- Engine side inspection hatch

- Fan attached to the pressure port with gaskets

- vibration dampers and by means of vibrostops on the feet

- Base and counter-base with interposed

- vibrostop

- Belt tensioner slides

- Transmission with V-belts and pulleys

- Steel panels

MCT series fan boxes are equipped with centrifugal double inlet transmission fan. Mounted motors are asynchronous three-phase IEC V. 230/400 Hz 50 or V. 400/690 Hz 50 IP 55 CLASS F. Dual polarity 4/6 Poles motors (1,400 - 900 RPM) are available on request. The temperature of the conveyed fluid must not exceed 40°C.

- Cerebro and/or Easy series switchboard

- Speed controller (single phase)

- Galvanized sheet metal rain canopy

- Wolf's mouth with anti-volatile net on presser

- Engine side inspection hatch

- Supporting feet

- Polished Stainless Steel Panels

- Standard dimensions can be varied by customer order and design

Can't find what you're looking for?